We appreciate all the comments on our posts. If there is a direct question to us, please use the contact us page to email us. We try to respond to every email. However, it is not easy to respond to the comments. Thank you!

The importance of routine maintenance to catch major problems

Below is a blog post that Gennady responded to recently regarding how important maintenance is for boilers.

https://forum.heatinghelp.com/discussion/185121/my-clients-heat-exchanger-got-blowed-up#lastest

Original poster - heat exchanger blew up:

It even blew the bolt heads off. We found it like this during a recent heavy rain. The flue was full of water. The condensate neutralizer was draining too slowly. I think they should rewrite the manuals to show flue piping terminating with one-two 90s. Many show a straight-up, open termination.

Gennady’s response:

I think the boiler was working for a while with a compromised gasket and/or studs.

We caught a similar problem on 2 million BTHU boilers during maintenance, done for the first time in 10 years after installation. Lucky client, these heat exchanger covers were about to fall off.

New services offered

A very large portion of our work is fixing other people’s installations. After the engineer or architect have finalized their drawings, after the contractor has installed what they felt was correct, after the work has been signed off with the DOB, the homeowner is left with their installation. We get many calls to fix what doesn’t seem to be working right. It is making too much noise, or the heat is just not as comfortable as expected.

We want to offer our knowledge to the homeowner, contractor, engineer, or architect before anything begins. If it’s done right the first time, everyone is happier with the outcome.

Reach out to us to go over your plans to see if you have accounted for every factor, are the plans specific enough to not allow for interpretation, do you need an additional level of control over the construction. We can provide this service.

Case Studies - Savings for steam system without new boiler

42 Apartment building in Brooklyn - 31,708 sq ft

Heating system - Oil fuel steam boiler providing heat and hot water to 42 apartments and 42 Bathrooms.

Complaints - uneven heating throughout and high oil bills

Solution - installation of master vents in specific areas of the building to allow steam to travel freely and quickly to each radiator; installation of thermostatic radiator valves on each radiator to allow occupants to control the heat level in each room; installation of storage tanks for domestic hot water to remove domestic hot water load from the boiler; and installation of proper heating controls with the correct set up.

We used heating degree days to determine the gallons used per heating degree day. We did not include domestic hot water usage in our savings calculations. The savings are based on heating only.

Prior to our work the average oil gallons used for heating during the winter over 16 years was 24,767 gallons. After our work was completed, the average gallons used for heating was 15,459 gallons. This is a 42% savings without replacing the boiler or fuel source.

Great article from heatinghelp.com - Air vents spitting or hissing

What a great article from Dan Holohan on heatinghelp.com. This is a great resource for heating questions.

https://heatinghelp.com/systems-help-center/spitting-or-hissing-air-vents/

Spitting or Hissing Air Vents

SHARING

Published: February 25, 2020 - by Dan Holohan

Categories: Steam

Here are some reasons why the air vents are hissing or spitting water on your one-pipe steam heating system (and where to look for solutions).

The system is dirty.

Steam heating systems are constantly corroding. The insides of the pipes get wet on each cycle, and then dry out as air rushes back in to fill the void left by the condensing steam. Over time, the pipes rust. Feed water brings in fresh oxygen, which causes corrosion. It also brings in minerals, which build up in the boiler. If no one cleans the system, the rust and mineral deposits, driven by the steam, eventually wind up in the air vents. When a vent can't seat tightly, it will spit water and hiss.

Other vents are not working as they should.

A hissing air vent is trying to tell you something, so listen! The air is rushing to escape because it doesn't have enough ways out of the system. As air vents fail, the velocity of the air leaving the working air vents increases. That's what makes the hissing sound. As the velocity increases, the particles of rust and minerals move more quickly toward the working air vents. Soon, those vents fail as well. If you can hear the vents venting, you don't have enough vents.

Take a good look at the system and clean or replace the clogged air vents.

There are no main vents on the system.

The key to balancing a one-pipe steam system is to vent the air from the mains quickly, and the air from the radiators in proportion to the size of each radiator. If the system has no main vents, the radiator vents have to do two jobs. They'll have to vent the air from both the radiators and the mains. That double duty increases the velocity of the air as it leaves the radiator vents, making them hiss. Inspired by the higher-velocity air, more debris works its way toward the vents, causing them to clog and spit water.

Every one-pipe steam system needs a main vent near the end of each main, but not right at the end in a tee. If the main vent is at the end of the main, water hammer might damage it. Place the vent at least 15 inches back from the end of the main, and up on a six-inch nipple. This gets it out of the way of any water hammer damage. If you vent the mains properly, the steam will travel more evenly through the piping system, and leave more slowly through each vent. That increases the life of the vents, and lessens the spitting and hissing problem.

The vents are the wrong size for their location.

There's a lot of air in a steam main so you should use a large vent that can handle a lot of air. If the vent is too small, it will hiss and eventually spit water as it fills with sludge. The same is true for large radiators. They contain a lot of air so you should vent them quickly.

With a large radiator, however, you're better off using two slower air vents instead of one quick one. Drill and tap the radiator for the second vent a few inches below the first vent. The two vents will work together when the steam first reaches the radiator. Then, when the steam reaches the first vent (the higher of the two) the second will continue to vent at a slower rate. Since there will be less air in the radiator at that point, the second vent will be properly sized. This is a Dead Men's trick that works wonders!

The boiler is oversized or overfired.

As you increase the amount of steam moving through a pipe you also increase the steam's velocity. The faster the steam moves, the more likely it will be to drive debris toward the air vents.

Size and fire a boiler to the connected load. No more, and no less.

The system has motorized zone valves.

When a motorized valve shuts, the firing rate of the boiler stays the same. As the boiler tries to move its entire load through the zones left open, the velocity of the steam increases. The faster the steam moves, the more likely it will be to drive debris toward the air vents.

Increase the size of the air vents, or use several main vents on a manifold near the end of each main.

What can you do to increase efficiency without a conversion to natural gas - Post 1 - Master Vents

Step 1 - Master Vents

Optimize your heating system by removing any wasted energy. Install master vents on all the headers and risers to ensure that the boiler is creating steam, not building pressure to push air out of the system. Master vents need to be installed systematically throughout the space. There is a calculation to ensure that the amount of master vents installed is sufficient to remove the air from the system and have steam fill the risers quickly.

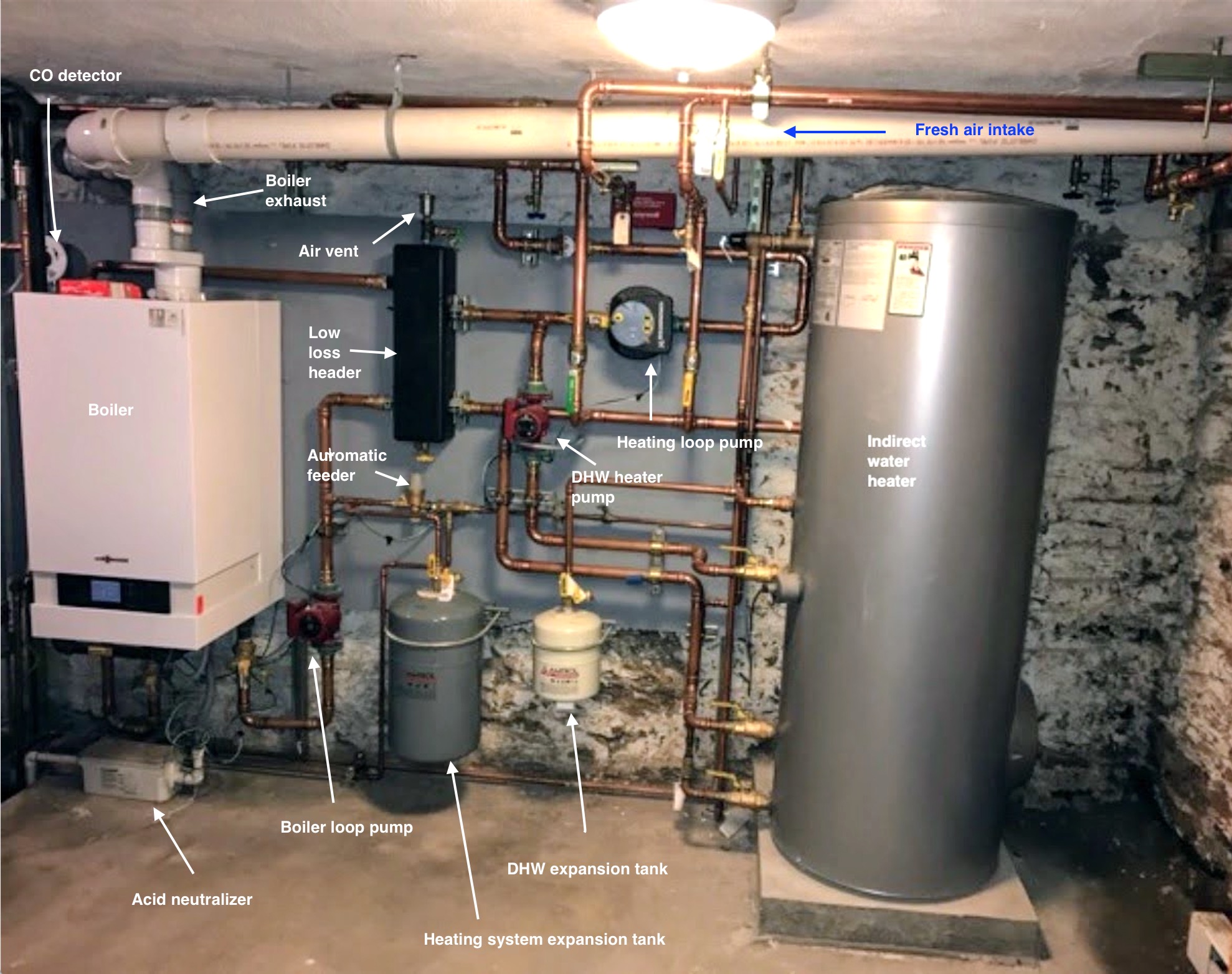

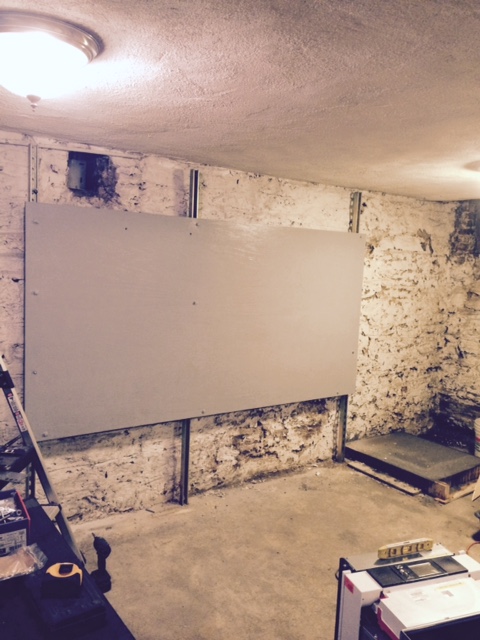

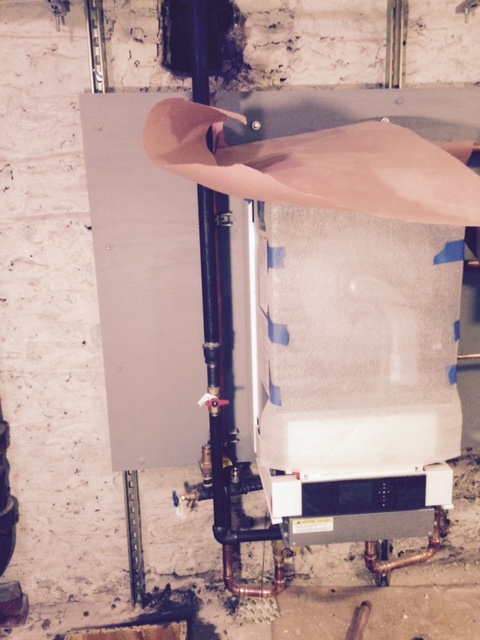

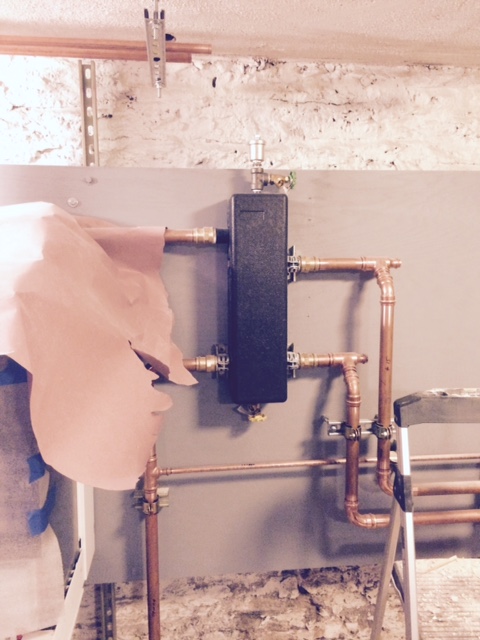

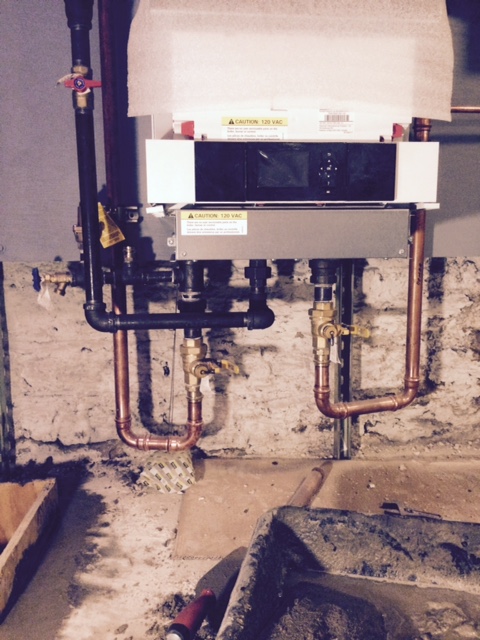

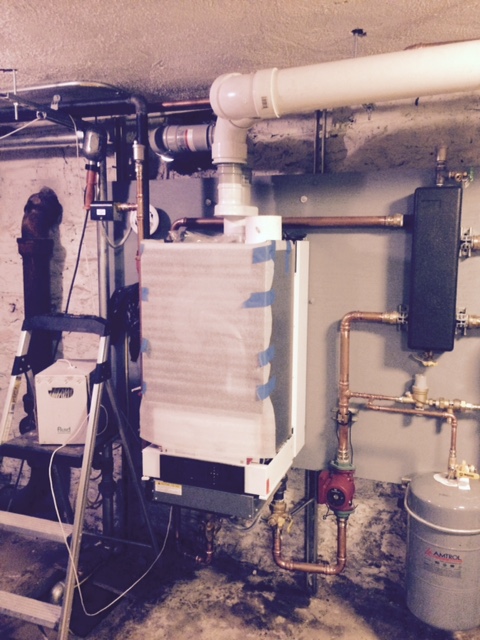

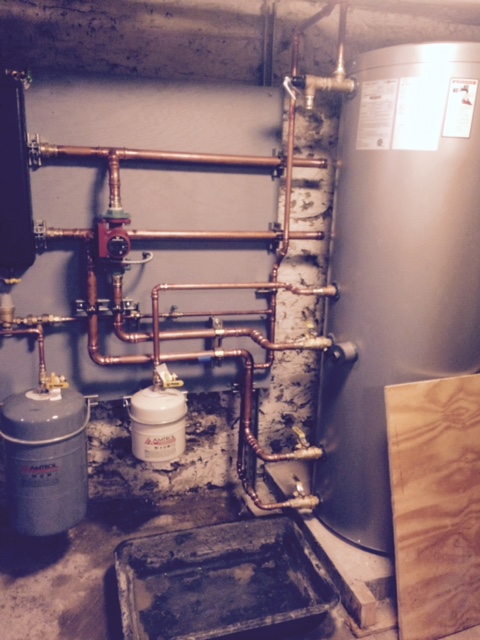

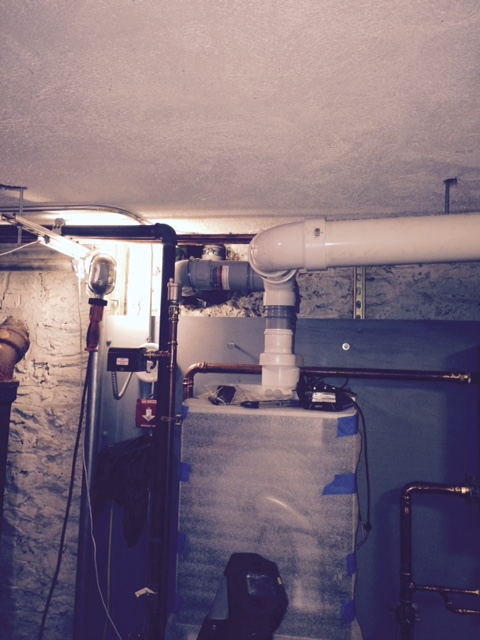

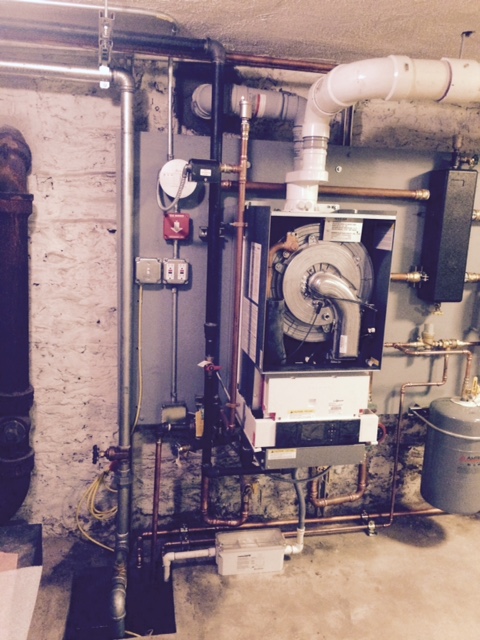

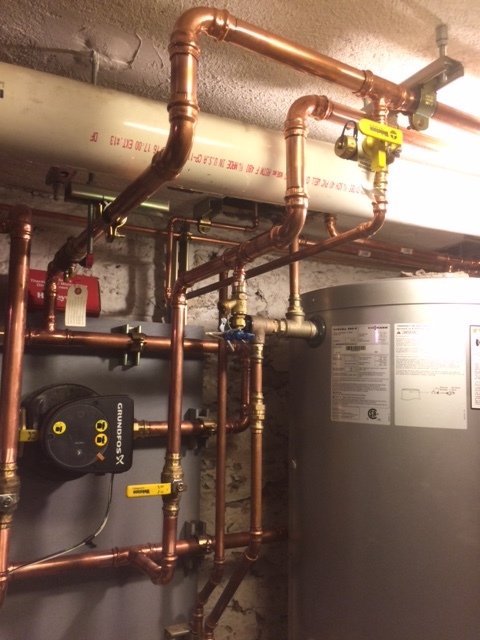

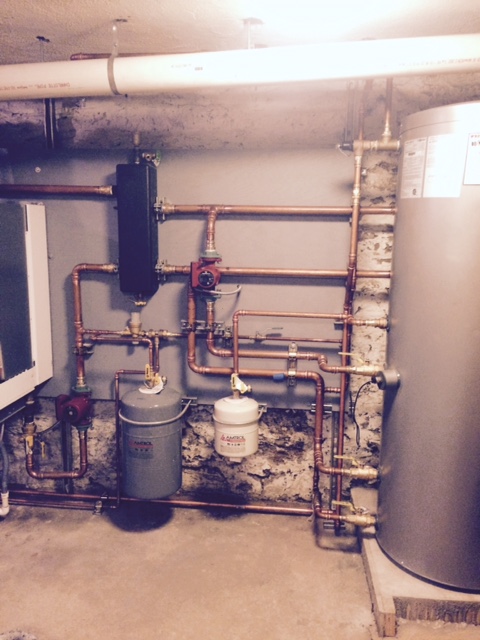

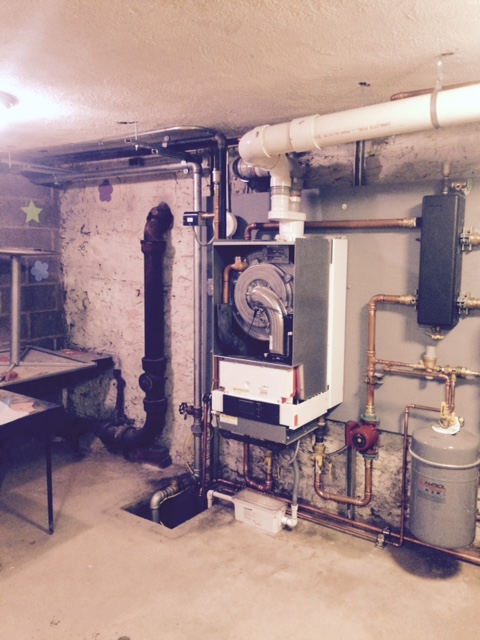

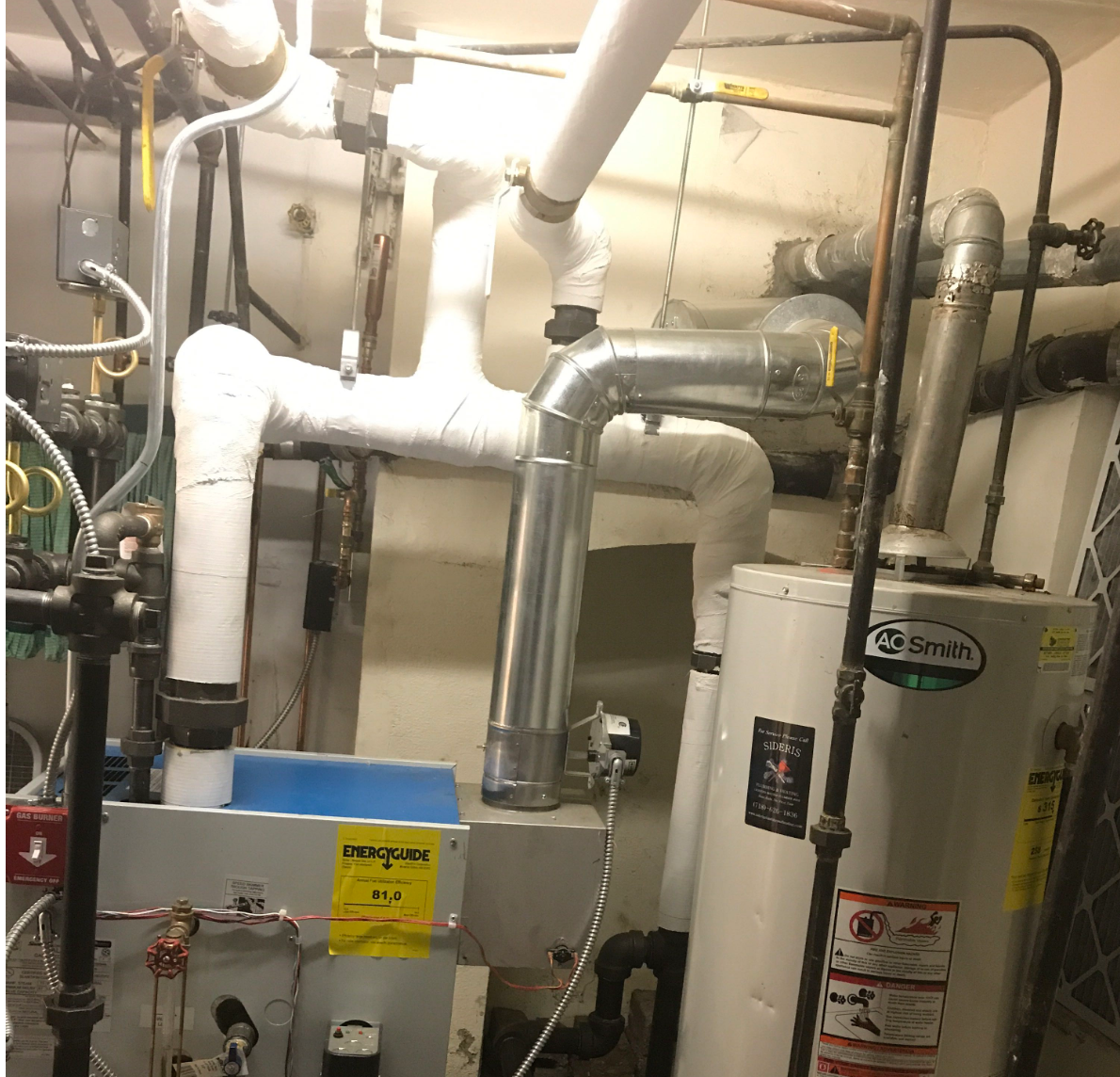

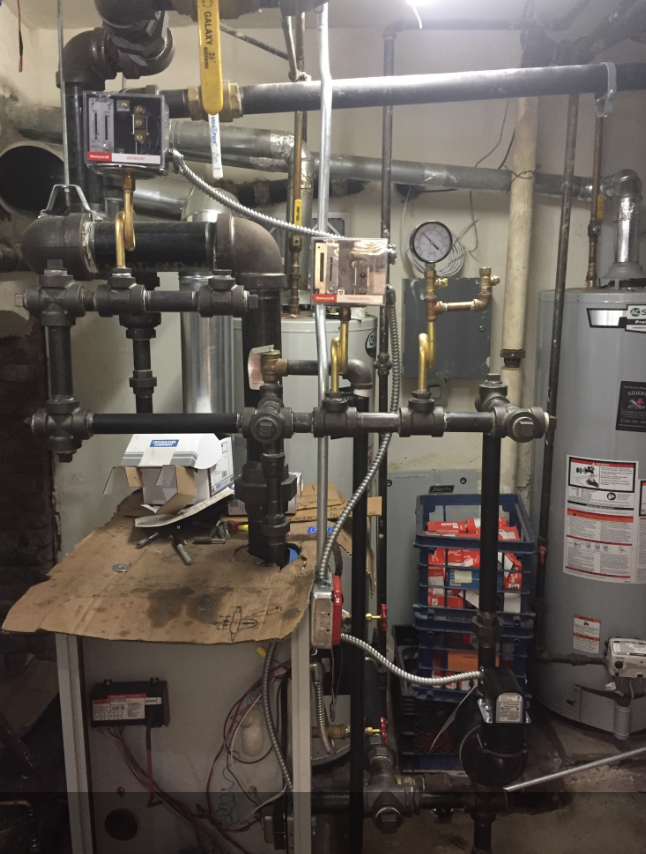

Viessmann installation

Here are a few cool things that are including in an installation of a high efficiency boiler by Absolute Mechanical. These items are pretty important for a proper heating system. The opportunity to replace your system doesn't happen too often, take advantage and install your new system the right way.

Air eliminator to automate air removal from the system. While the system will need to have the air removed upon initial start up after the installation is complete, air doesn't need to be manually removed throughout the season.

Variable Frequency Drive system pump - this pump adjusts speeds depending on the conditions of water flow in the system and saves up to 80% in electricity.

Installation of boiler pump - this pumps moves water through the boiler loop while the VFD system pump (noted above) moves water through the system loop.These loops are connected through low loss header.

Dirtmag (not pictured) serves as a filter and magnetic rust catcher to collect the dirt and rust coming from the system to protect the boiler and pumps.

CO detector interlocked with the boiler - the CO detector is hardwired to the unit will shut down the boiler in case CO is present.

Acid neutralizing kit and drain line - the condensate from the boiler is acidic and needs to be neutralized before it is disposed into the common sewage.

Oil to gas conversion post from 2015

Below is one of our posts from 2015 which is very relevant now that the gas moratoriums are starting.

Do I need an oil to gas conversion to be more efficient

The idea is that an oil to gas conversion will save you money in the operation of your system. This is true as gas is about 30% less than oil per BTU of heat. Therefore you can lower your bills just by changing the source of fuel. However, you can save even more just by looking at your existing system. By optimizing, upgrading, and updating your heating system with modern techniques and technologies you can save over 50% without converting to gas. These techniques should also be implemented if you choose to convert to gas anyway to see a savings of over 70%.

The boiler is just one part of a very intricate system. All parts need to be addressed to get the most out of the system.

Balancing steam and hot water systems, installation of outdoor and/or indoor reset controllers, variable frequency drive pumps, insulating of all piping, correcting sequence of operation, are just a few measures to name, making huge impact on efficiency and comfort of the heating systems.

The Williams pipeline and potential moratorium on oil to gas conversions in NYC

Below is a summary from Politico regarding the Williams pipeline and the utility company’s options if the pipeline is not approved. While it is still unclear if a moratorium on new gas lines will be implemented, it is still a possibility.

With this new information, what are the options to the homeowner in these areas who is currently on oil?

Well, you don’t have to wait for electric or the moratorium to be over to make your system more efficient and save money. While in the past, oil was more expensive than gas and a conversion was the biggest way to save, current upgrades in the heating industry have provided products that can save you money and provide great comfort without having to go through a big conversion.

You can upgrade your heating system while keeping the same boiler. A few simple modifications and some attention to your existing boiler can extend the lifespan of your current oil boiler. We will be posting these various options in a separate blog post over the next few days.

https://www.politico.com/states/f/?id=0000016a-12cb-da8e-adfa-3adb6f5d0000

Measuring indoor temperature

One of our biggest and easiest recommendations for building owners and managers is to arm their supers with a thermometer. It is such a small investment that yields such savings and rewards. Everyone has a different comfort level in terms of heat. Some people want to have 80F and some want 68F. When a tenant complains they usually say “I’m cold, the heat must be off”,”The radiator is cold, the heat must be off” but this doesn’t give any information to the owner, technician, or super. NYC mandates that building’s provide 68F. Many no heat calls can be solved without a technician.

The super can test the temperature and determine one of the following - is the heat sufficient, is it completely off (sometimes the building heat can be on but the apartment’s radiator is off or has a broken air vent), is the heat level sufficient but not comfortable for the tenant, etc.

In our company we use the Testo thermometer and recommend every building provides one to a super, shareholder, or tenant.

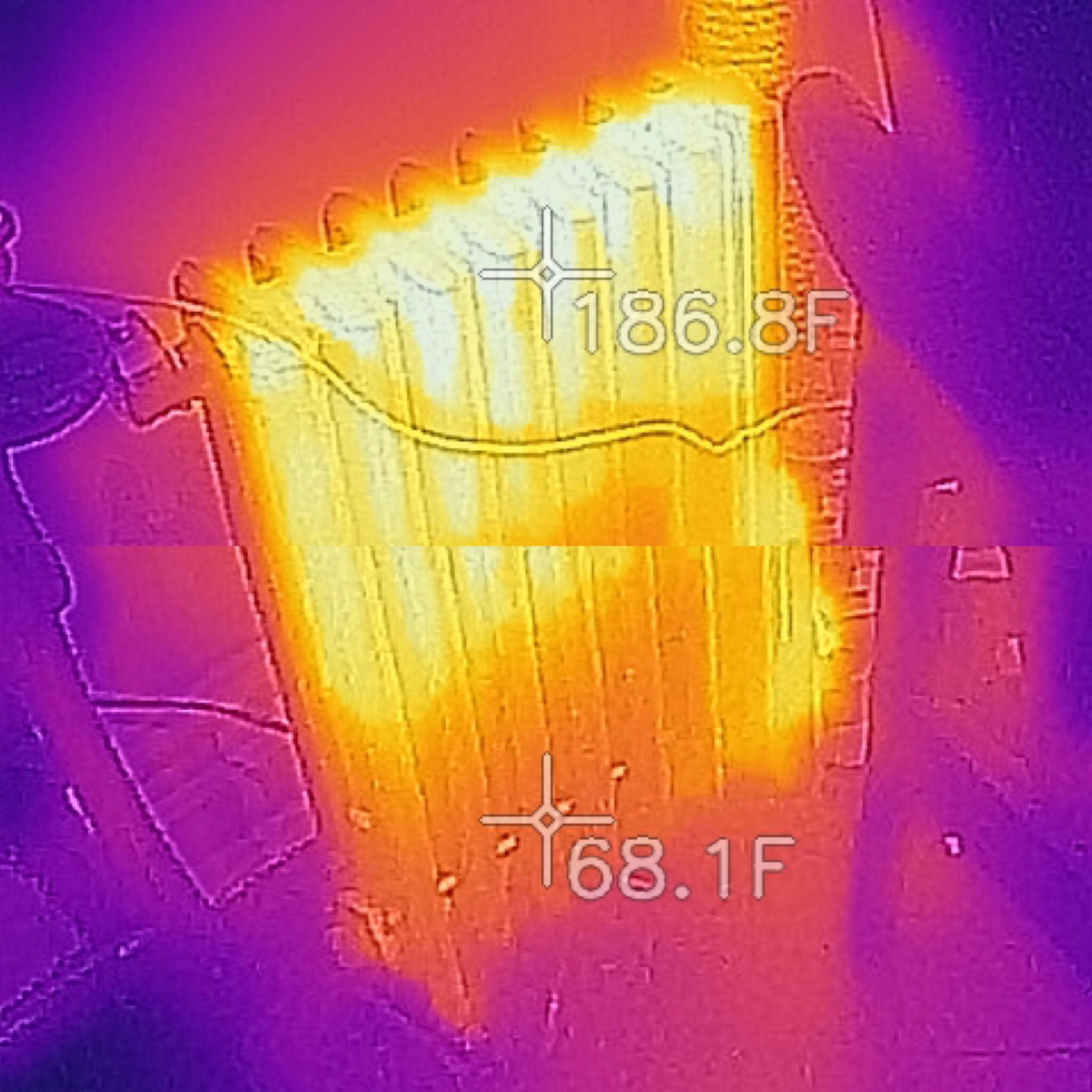

Below are pictures from a recent “radiators aren’t working” call.

Gas Regulation Update

The PDF below explains the new Local Laws that are in effect related to gas work in NYC.

Gas by the Numbers PDF as presented by Master Plumbers council

Absolute Mechanical - Gennady's Videos from Youtube

https://www.youtube.com/user/absoluteinbrooklyn/videos

Hydronic heating - series to parallel corrections

A very common problem in new constructions is the installation of radiators in series. This means that the return of one radiator is the supply of the next and the next after that one. This means that the first radiator receives all the hot water, the second one a little bit less, and the 3rd/4th/5th receives very little. We see this along single apartments or through several apartments. The problem is that the first room will be over heated while the next rooms won't have enough heat. We also see TRVs installed on the first radiator. In this case the occupant of the first room will turn the TRV down since they are getting all the heat, which will turn the heat off for the following rooms.

The solution is to convert these radiators from series to parallel. Below is an explanation from Danfoss on how this is done as well as some pictures of our conversions from series to parallel.

Work in Progress - Steam Installation in Manhattan

Installation of a new slant/fin 100,000 BTU steam boiler for a 3 unit + commercial space in Manhattan. We installed master vents and TRVs along with the new boiler to increase comfort, efficiency, and properly size the boiler. The old boiler was 280,000 BTUs and to our surprise the installed EDR was only 55,000 BTUs for the whole building. The commercial space has so many people and equipment that it typically doesn't even require heat. Luckily for them, the installed TRVs will control the first floor so they no longer over heat.

The old boiler was so oversized that it had severely corroded. It's unlikely it would have survived another winter.

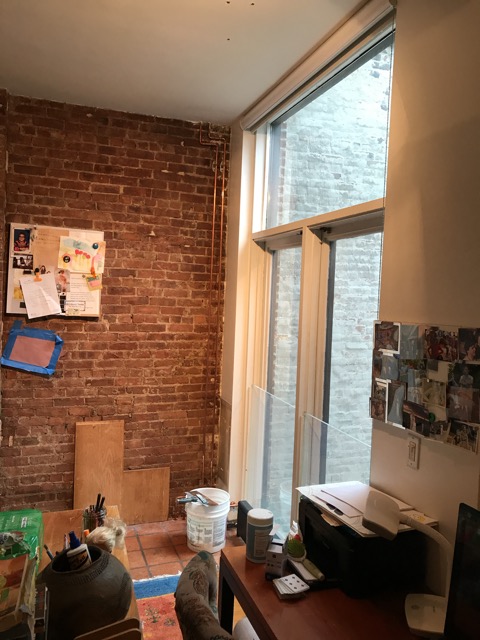

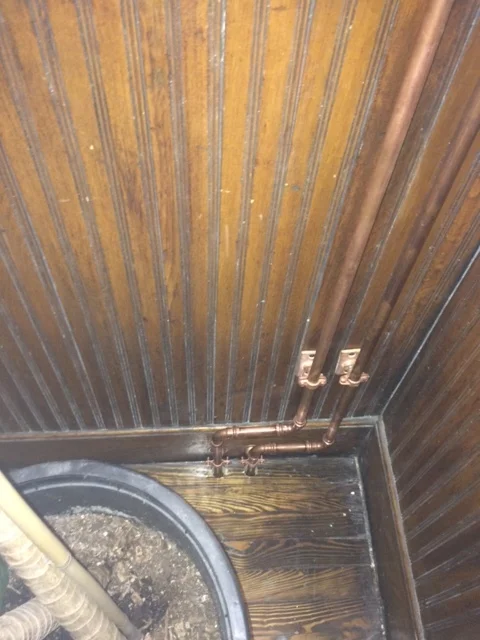

Before pictures:

During and After Pictures:

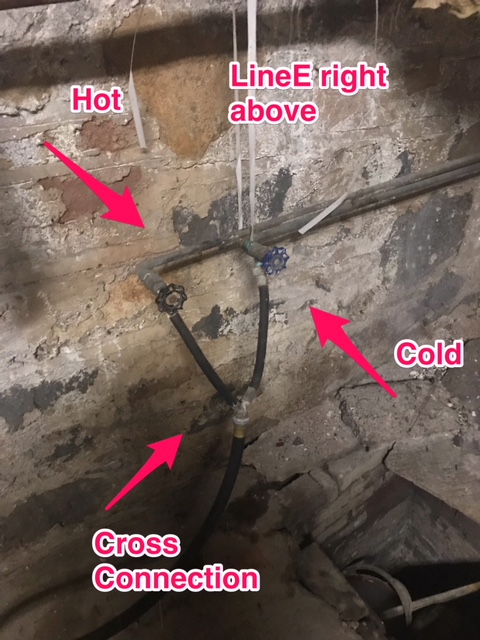

DHW Cross Connections - Y Connection

Here is a picture of a Y connection in a building that caused a wild goose chase to figure out why one apartment line had continuing hot water issues. Someone had install these Y connections for their own use, not knowing that this is actually cross connection between cold and hot water lines. Cold water enters hot water line and stops the hot water from going to the apartments.

The importance of performing maintenance on your heating system.

Maintenance of a heating system is extremely important. This is not just blowing off the dust and making sure the boiler sits pretty. It involves intense cleaning of all important components of your heating system as well as introduction of chemical treatments that increase the longevity of your system.

Boiler components are exposed to the elements and harsh conditions while your system is operating year round. Without proper maintenance these parts can break when they don't have to. Many times a replacement will be recommended for a part that just needs to be cleaned.

Below are pictures of a LWCO of a system that's been operating for only one year. We see this on many boilers.

I'm hot / I'm cold and false alarms

Prior to calling out your tech for any adjustments to the boiler you should check the following:

- What is the temperature in the room vs what temperature you would like? While the temperature in the room is scientific, the comfort level is subjective. It is important to know the actual temperature in the room to see if there is an issue with the system or you just want it to be warmer.

- Are your radiators open? Very often people shut off their radiators due to some over heating that may have happened a few days ago and completely forget. Then a service tech is called out to check on the system, they don't understand what is going on, the boiler is working, the building has heat, but the apartment is cold.

- Is your window open? Very strange to ask this question but oddly enough, we come out to a lot of service calls where the window was opened and then forgotten. New York apartments very often have poor windows that no longer lock which allows the top of the window to creep open without anyone noticing. This 1 inch gap can be the difference between a comfortable New York winter evening and a miserable one.

- What is the temperature outside? Most heating systems are designed to turn off when the temperature outside goes above 55-56F.

Great article post from Erin Holohan of Heatinghelp.com:

Want to learn more? Check out We Got Steam Heat: A Homeowner's Guide to Peaceful Coexistence.

-- Check out www.heatinghelp.com for great heating Q&A, historical steam stories and explanations. It is a wealth of information from heating professionals across the country.

Steam Air Vents

We often see air vents installed incorrectly on a steam radiator. These radiators can be installed for both steam and hydronic systems and therefore have two available ports. The top one is for a hydronic system bleeder and the bottom one is for a steam system. However, many people don't know this and use the top port for the air vent installation.

This blocks half the radiator from warming up because steam is lighter than air, it travels right up to the air vent and closes it leaving half the radiator without steam.

Below is the heat distribution on a steam radiator with the air vent incorrectly installed on top of the radiator (upper left here).

Update - West 88th Street - Project Completed

Completed conversion from electric to hydronic heating system with the installation of a new Viessmann boiler, storage tank, and radiators. The radiators were a combination of Baxi, Runtal, and Governale radiators depending on the style of the room. All radiators were installed with TRVS. Supply and return lines were installed in copper with propress fittings. Below are the pictures from the project.