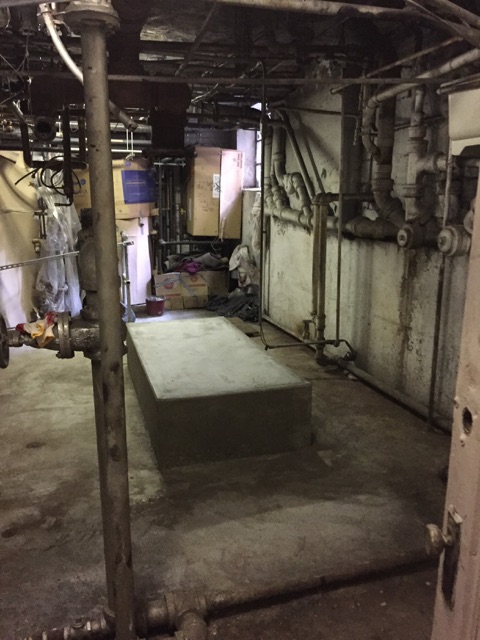

One of our current projects is a conversion from an electric heating system to a hydronic heating system in a two unit brownstone in Manhattan. Currently each apartment has their own electric baseboards and are paying a fortune for heating. We are installing one Viessmann Vitodens boiler for the building for heating and domestic hot water as well as baseboard radiators. Phase one of the project is to install the boiler in the basement.

How to Start Looking for a Boiler Installer

The process of finding a contractor can be very overwhelming. You may not even know where to start. You can start with asking friends and neighbors about who installed their boiler and were they happy with the installation. You can look online for boiler installers in your area or on your local blogs. Once you find one or two installers you like, keep up communication with them. Perhaps you are not ready to invest right now or the price seems higher than expected. Continue communicating and asking questions, even questions like "why is the price so high" or "why are you offering this instead of that". As the customer, you should not be ashamed to question the contractor. Asking questions will lead you to a better understanding of the product you are getting and the type of company you may decide to work with. Sometimes the way a contractor handles your questions is a good indication of how they will handle your project, house, and future complications if they arise.

Heatinghelp.com and brownstoner.com are two great sources in the NY area for references and answers to any questions you may have about the process.

Here is a blog post where Gennady describes the best way to go about finding an installer.- http://www.brownstoner.com/forum/#!/general-discussion:boiler-installer-recommenda

"Do the search on internet. Use keywords like “boiler installer in brooklyn”. Do not look at advertisements results, look at natural search results. Also visit heatinghelp.com “find contractor” section. Look at local boiler installer companies websites. Then go to dob website, a810-bisweb.nyc.gov/…/icenseTypeServlet?vlfirst=Y check if contractor on the website is licenced. Then do the search on candidates, see how many boiler jobs they did recently. Boiler work is a specialty, so you must find contractor who does boilers exclusively. See LAA and permits information regarding clients. Contact clients and ask them about their experiences with contractor and job in general. Make sure contractor offers heat loss calculations and EDR survey. Do not rely on size of existing boiler. You don't know if original installer did not do mistake in sizing of the boiler years ago. Another consideration: do you want just to replace boiler or upgrade it to better one, more efficient, do you consider upgrade heating system in general."

Follow Gennady's comments on forums

Brownstoner.com and heatinghelp.com are fantastic sources of information for home owners and contractors. These are great tools to get information from knowledgeable contractors or experienced homeowners. Gennady is a frequent contributor to postings on both forums. Below are some recent posts that he's commented on.

http://forum.heatinghelp.com/discussion/157347/manifold-versus-trvs#latest

http://forum.heatinghelp.com/discussion/157488/thread-sealer-for-2600-psi#latest

http://www.brownstoner.com/forum/#!/general-discussion:boiler-installer-recommenda - Great question and answer about how to start looking for a contractor

Installation of Master Vents

This is an issue we see in so many buildings. We come to a building where the bills are very high and yet half the building has no heat. When we walk through the building we find that the headers are being vented with one tiny radiator air vent. Venting is a science like any other aspect of heating. There are calculations that need to be performed to figure out how much venting is required and correct locations for these air vents to be placed. Below are a few pictures of vents in a building.

Venting Headers:

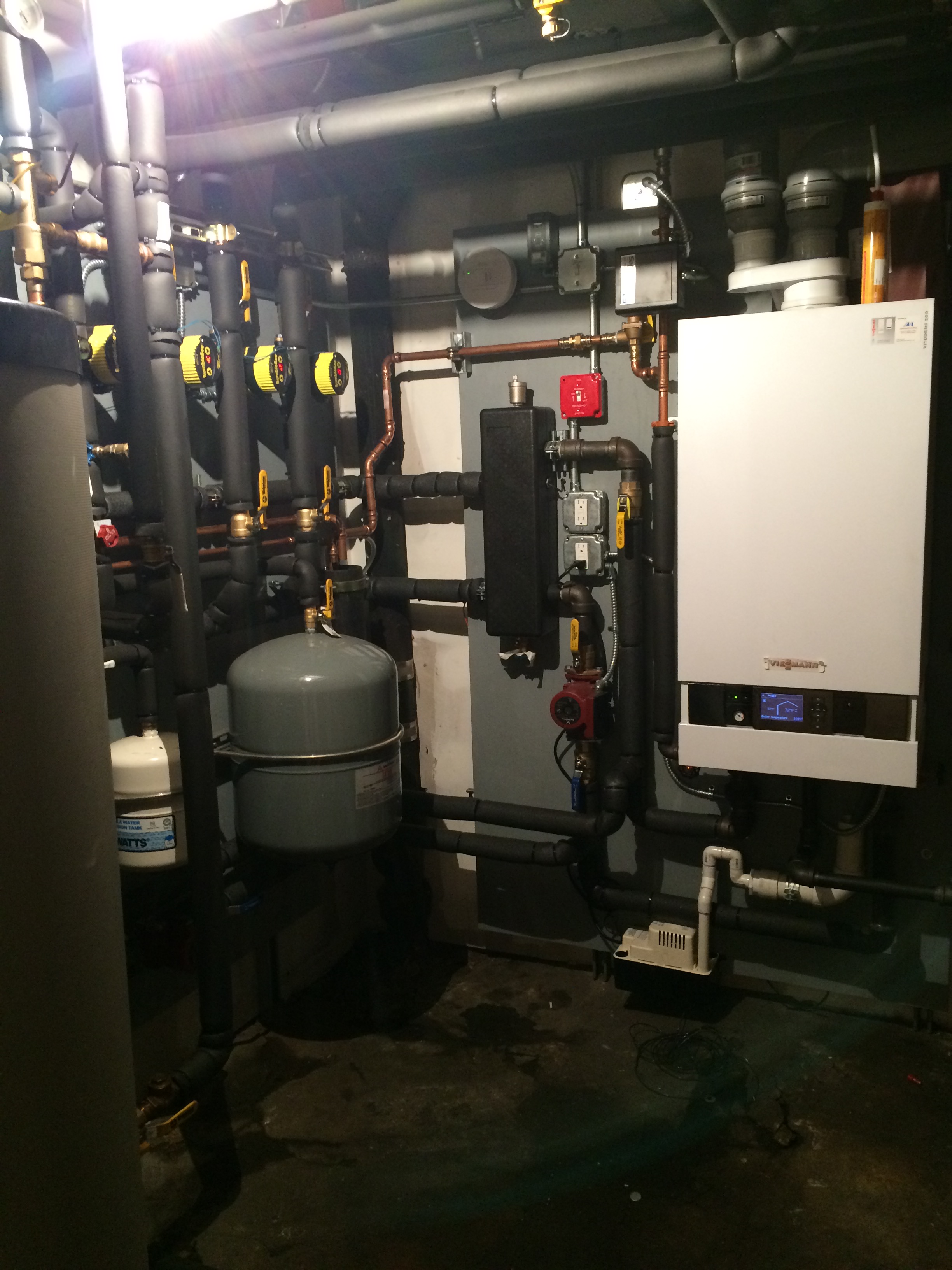

Park Place - Job in progress - Viessmann CU3A-35 installation with Radiant

We are currently in the process of installing a new Viessmann CU3A-35 boiler with a radiant heating system in Brooklyn. This is Viessmann's latest residential boiler. We are very excited to be installing it along with Caleffi Manifolds and Ultra Fin radiant tubing with copper supply and return lines to all pex and manifolds.

The importance of CO detectors - A story

Our installations come with a CO detector interlocked with the boiler. This is extremely important as the boiler will shut down if CO is detected. About 2 years ago we installed a boiler in a loft in Manhattan (apartment 5R). As a precaution we installed two CO detectors, one inside the boiler room and one outside the boiler room. There were also 2 CO detectors installed in the loft as additional precaution by the owner.

Recently the tenant in the apartment claimed that the CO detector outside of the boiler room had been going off and he was very worried that the system was producing dangerous levels of CO. We came out and checked our heating system and didn't find any evidence of CO in the boiler room. A few weeks later, the CO detector went off again. This time he became very nervous and moved out of the space until the issue was resolved. The apartment owner purchased a CO monitoring device which records levels of CO and keeps the highest one in memory. On a warm day when our system was not operating and the tenant was not in the space using hot water, the CO levels reach 89. The owner of the property called in a very knowledgeable building investigator who went through our system and all the systems in the condo building. What they found was extremely disturbing.

Below is an excerpt from their report:

"After thorough examination of apartment 5R's heating system, a high efficiency condensing hot water boiler with a tankless domestic hot water component. This system has a carbon monoxide detector in the equipment room. The system was found to be in good operating condition, there were no observable signs of combustion gas leakage.

... The first issues I observed was that the direct vent gas boiler for apartment 3R boiler has a cracked exhaust vent, this is leaking combustion gases into the building and is a source of the carbon monoxide. "

The report also found that every other boiler in the building was being vented illegally and incorrectly.

"With the use of a smoke stick, I found that the combustion gases were being blown back into both the apartments for both apartments 3R and 4R. These water heaters were not installed as per manufacturer's instruction or per New York City code..."

The only reason that any of this was found out was because we had installed CO detectors as part of our installation. This instance goes to show that you can do everything right and still get into an issue because of someone else's incompetence. Buildings are required to have smoke alarms as well as CO detectors installed, yet very few of them do. The residents of this building were very fortunate to have this issue found out before any casualties occurred.

Oil to gas conversions for steam systems

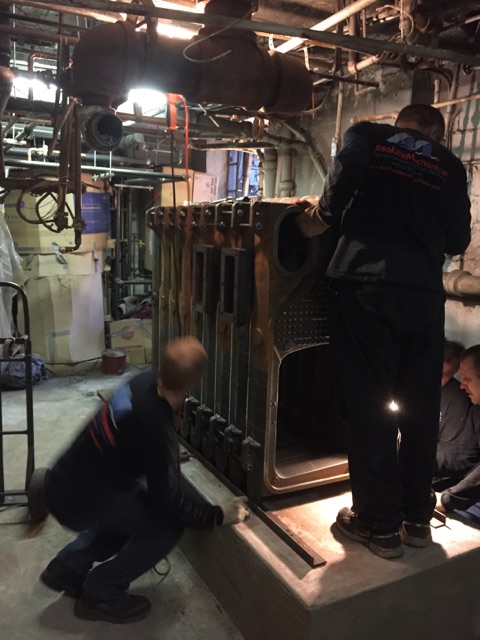

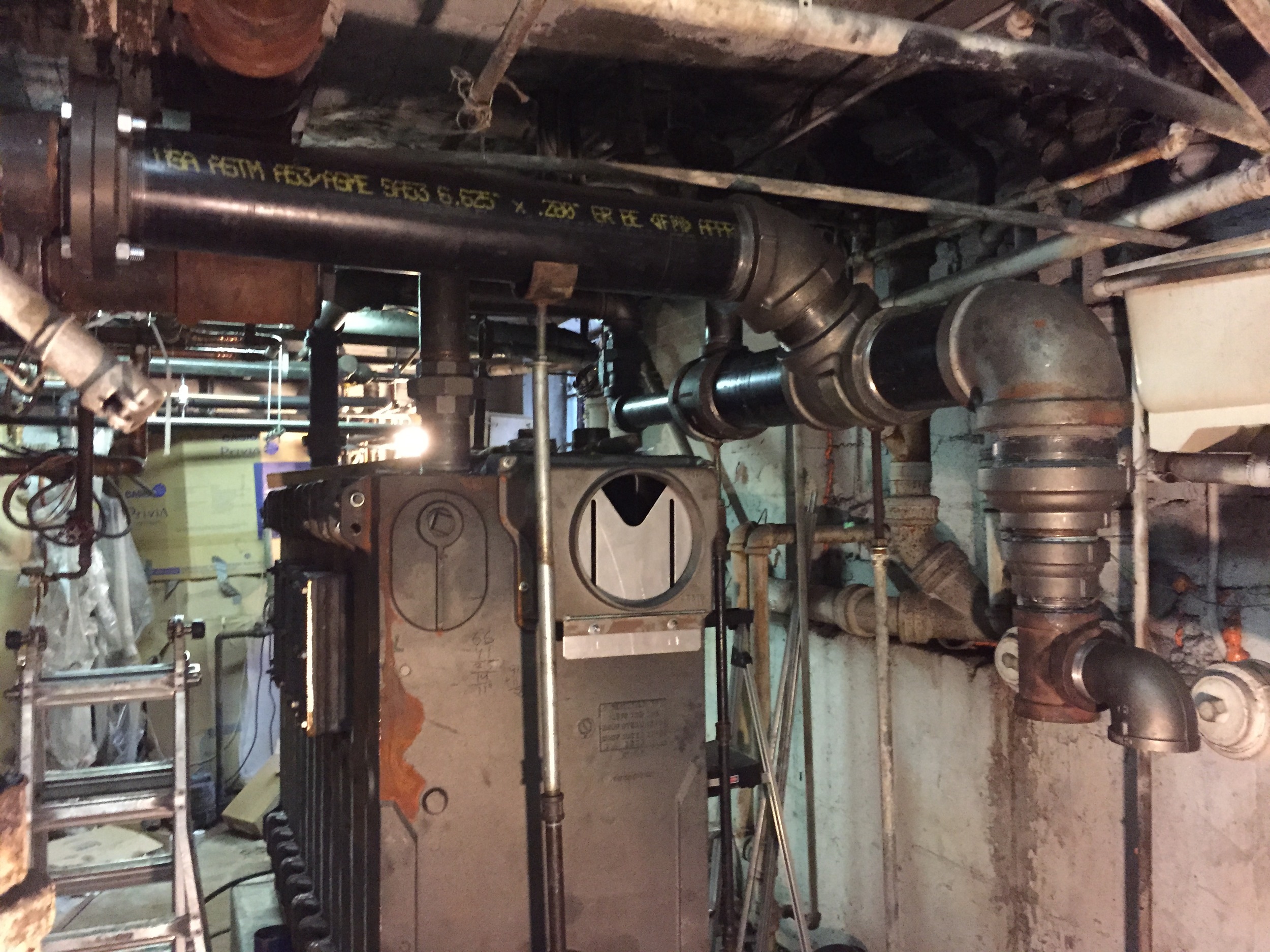

We are currently in the process of converting a 39 unit building in Manhattan from oil to gas. Below are the pictures of the process and the size of the boiler before and after.

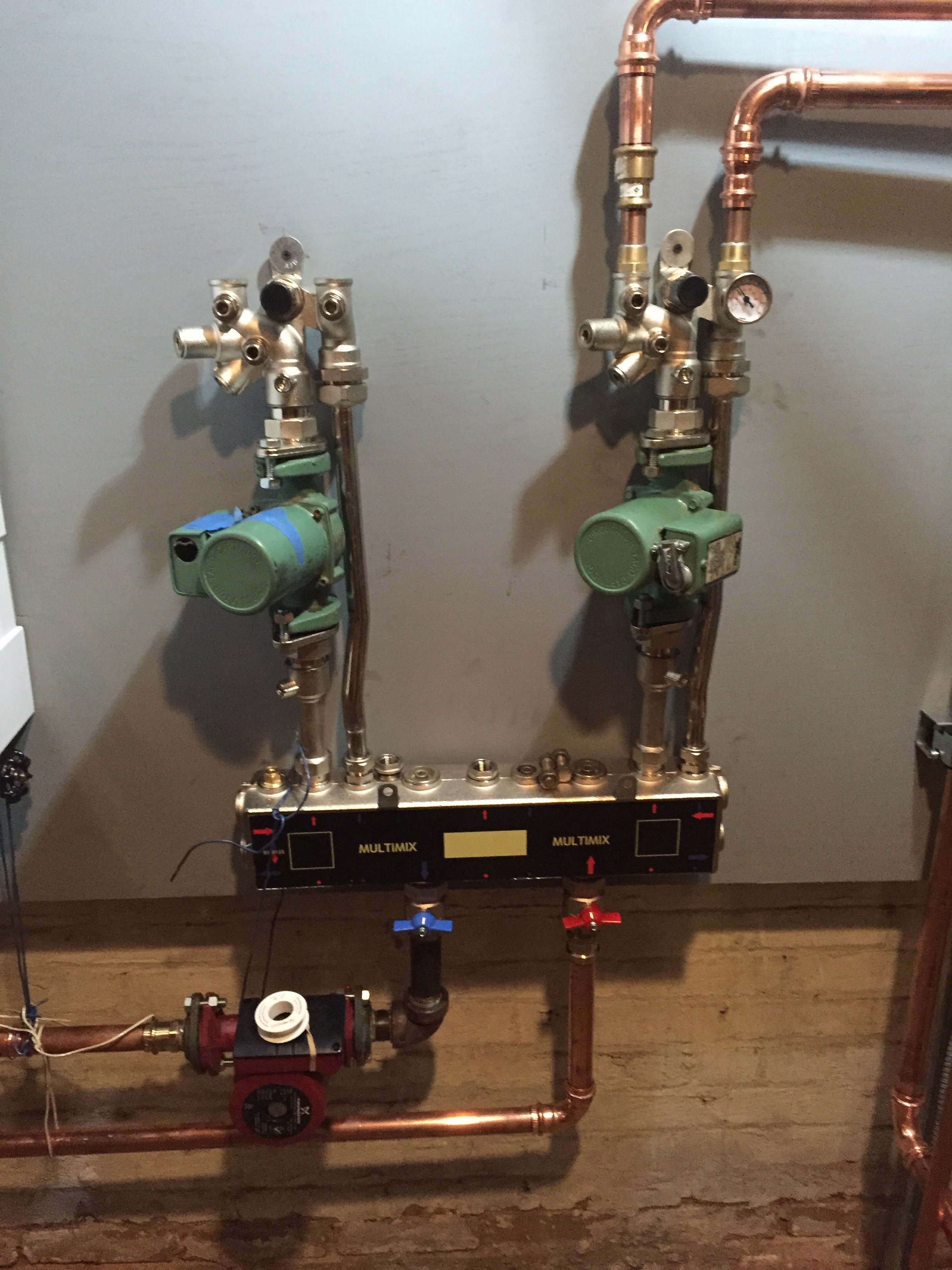

New Viessmann installation with IVAR

We are currently installing a new viessmann vitodens boiler in a brownstone in Brooklyn and using the IVAR system for the near boiler piping. This is extremely exciting for us as we love to experiment with new technology.

Stories from the field - missing valves and drains

We often see boilers that are missing very important valves and drains which would prohibit proper maintenance from being performed. Many times the owners tell us that the boiler has had maintenance performed every year like clockwork. However, when we look at the boiler they are missing key components that would allow for maintenance to be performed. Below is just one example. We were requested to replace a leaking coil in the boiler and noticed there were no drains installed on the boiler.

We wondered, how does the maintenance company blow down low points to remove sediments from boiler if there is no portal for this to be done. After we opened the boiler to replace the coil and saw what was inside we realized the simple answer was, they didn't.

This is what was found on the water side of the boiler. This layer effectively isolates flame from the water and reduces boiler efficiency drastically.

The poetry of the installation of a steam system - Absolute Mechanical

When we install a new boiler we diagnose the entire system. This includes the production of heat and distribution of heat.

We want to make sure that each stage of the heating process is done correctly and efficiently. This includes the boiler (sizing, cleaning, installation, supports, etc); near boiler piping (all the piping within 15' of the boiler will be completely brand new, in the proper configuration, and insulated); boiler controls and devices (all the controls will be brand new and the latest technology); production of hot water in a manner that makes sure there is no loss of energy; installation of master vents to make sure that the boiler is not operating to produce pressure to push steam but that steam flows through the system entering each radiator at the exact same time; TRVS on all the radiators to dynamically adjust their output based on the conditions of the room; and the redlink to determine the buildings indoor conditions (if the coldest area is satisfied then no more heat is needed).

Our steam systems are unlike any in New York. An installation by Absolute Mechanical ensures that there will be no more steam hammer noise, no more over heating or dips in temperature, and no more dry air.

How to adjust danfoss thermostatic radiator valve (TRV)

Number 1 and number 3 represent pointers. Depending on how you look at the valve you turn handle with numbers 2 and 4 on dial to align with pointers. You have to align number on scale 2 with pointer 1 or number on scale 4 to align with pointer 3. These 2 scales are identical and you can use either one of them. The number you pick represents temperature in the room. Start with number we set for you. We picked starting point for you. Try it for a day. The day must be chilly, like 50F or lower outside temperature. Do not do it when it is warm outside. If you feel cold go up 1/4 of the space between 2 numbers to the time. If warm lower setting 1/4 of the space between numbers. Try it for another day. Do not go to extreme setting either way right away. Your body has to accommodate to room conditions. It is different type of heating and you will love it when you find proper setting.

Removal and disposal of oil tanks

Removal and Disposal of Oil Tanks

NEW YORK CITY ADMINISTRATIVE CODE TITLE 29

NEW YORK CITY FIRE CODE

3404.2.14 Removal and disposal of tanks.

Removal and disposal of tanks shall comply with the requirements of Sections 3404.2.14.1 and 3404.2.14.2.

3404.2.14.1 Removal. Removal of aboveground and underground tanks shall be in compliance with the following requirements:

1. Flammable and combustible liquids shall be removed from the tank and connecting piping.

2. The tank and connecting piping shall be rendered free of flammable and combustible vapors using an inert gas.

3. Piping at tank openings shall be disconnected.

4. Piping shall be removed from the premises. Exception: Piping may be sealed in place where the commissioner determines that removal is not practical. Sealed in place piping shall be capped and safeguarded by filling with concrete or other approved material, and the fill connection removed from the fill pipe.

5. Tank openings shall be capped or plugged, leaving a 0.125-inch to 0.25-inchdiameter (3.2 mm to 6.4 mm) opening for pressure equalization.

6. Tanks shall be removed from the premises.

3404.2.14.2 Disposal. Tanks and piping shall be disposed of lawfully.

(d) Permanently Out-of-Service Storage Systems

(C) For fuel oil storage systems with a total capacity of 330 gallons or less, the closure shall be performed by a person holding a certificate of license or by a person who is employed and supervised by a person holding such certificate, by a person holding an oil-burning equipment installer license issued by the Department of Buildings or by a person who is employed by and under the direct supervision of a person holding such license, or a plumber licensed by the Department of Buildings.

(2) Affidavit of compliance. The owner or operator of a permanently out-of-service storage system or the permit holder for such system shall file with the Department an affidavit certifying that such system was removed and disposed of, or abandoned in place, in compliance with the requirements of FC Chapter 34 and this section. Such affidavit shall be executed by a person with the requisite qualifications to supervise the closure of such tanks.

Zoning and Efficiency of High Efficiency Boilers Operating on Outdoor Reset

I always see high efficiency modulating boilers installed with zoning control. Unfortunately this can't be correct due to the way modulating boilers are designed to operate. Modulating boilers should operate on outdoor reset, meaning that temperature of the water going to the heating system changes depending on outdoor temperature and flow of the water through the heating system remains constant.

The lower the outside temperature gets, the hotter the water that is pumped into the heating system. When it is warmer outside, the water temperature going to heating system gets cooler.

If one zone is turned off or set to a lower temperature for a period of time then when the homeowner needs this space to go into normal heating mode it will take hours to heat the space to the desired temperature. This space needs a water temperature higher than the one set by outdoor reset control of the boiler to get heat delivered fast. Some contractors bypass this by deciding to program the boiler so water temperature will be raised over the one set by outdoor reset for a limited time to heat this one zone faster. Yes, right, but at the same time other zones will be overheated.

Zoning of systems controlled by outdoor reset cannot be done with zone valves or pumps. It must be done with outdoor reset mixing valves, and reset curves and boosts must be set for each zone. It might be cost prohibitive and impacts efficiency of the system.

Do I need an oil to gas conversion to be more efficient

The idea is that an oil to gas conversion will save you money in the operation of your system. This is true as gas is about 30% less than oil per BTU of heat. Therefore you can lower your bills just by changing the source of fuel. However, you can save even more just by looking at your existing system. By optimizing, upgrading, and updating your heating system with modern techniques and technologies you can save over 50% without converting to gas. These techniques should also be implemented if you choose to convert to gas anyway to see a savings of over 70%.

The boiler is just one part of a very intricate system. All parts need to be addressed to get the most out of the system.

Balancing steam and hot water systems, installation of outdoor and/or indoor reset controllers, variable frequency drive pumps, insulating of all piping, correcting sequence of operation, are just a few measures to name, making huge impact on efficiency and comfort of the heating systems.

Absolute Mechanical Interview!!

Absolute Mechanical was interviewed for Long Island for sale to provide their readers with more information regarding heating systems. Please check out our interview on Long island for sale.

http://www.longislandforsale.com/articles/professional-advice-on-boiler-replacement

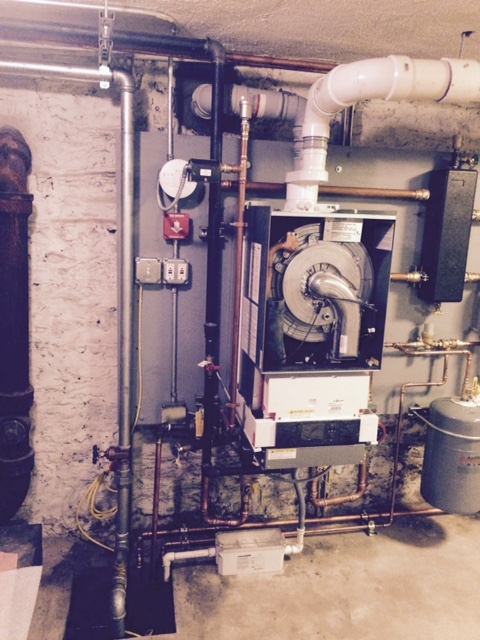

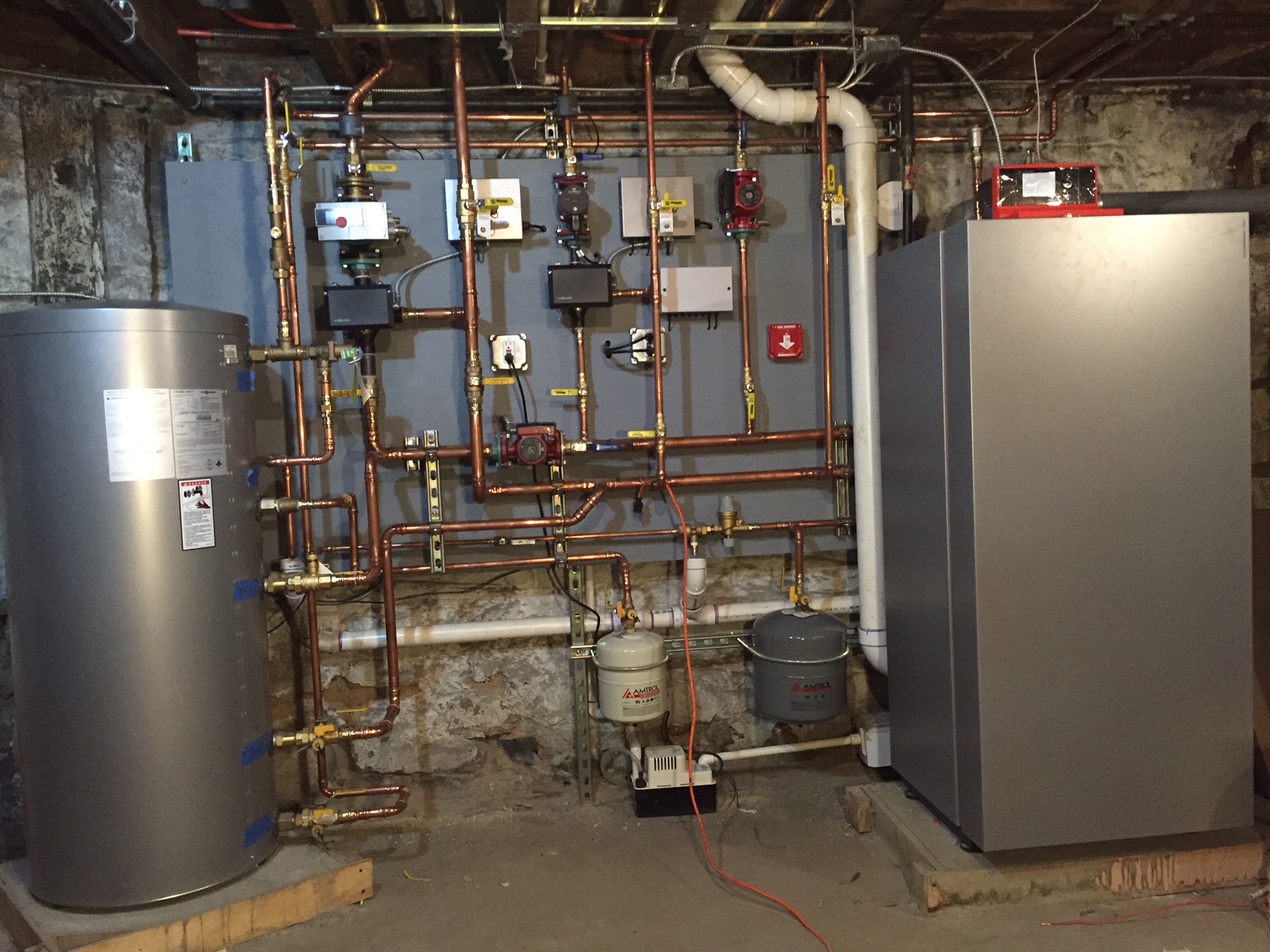

West 22nd Street - Oil to gas conversion - Viessmann

Absolute Mechanical has finally completed it's West 22nd street project. The boiler room is on the bottom floor of a duplex in a 4 unit building. The original boiler and oil tank took up an entire room of a Manhattan apartment and emitted an extreme amount of noise and heat! We installed a brand new mechanical room with a new Viessmann boiler and indirect hot water heater for this unit. It freed up an entire room for the apartment as well as a gorgeous installation for them to admire.

West 90th Street - Steam Boiler - Oil to Gas Conversion

This is a steam boiler installation with Thermostatic Radiator Valves and an internet enabled thermostat which allows the owner to view the temperature in the building from anywhere in the world.

The first picture is the original boiler, all the pictures after are the after and during the installation.

The completion of 43rd Street - Viessmann

This video is from the first day of the boiler installation. Please note that when there is something done that will cause dust we close up the space entirely in plastic so no debris enters the living space.

This was our first installation of the new Viessmann 222-F. This system is a great solution to the problems that arise from tankless combi boilers on the domestic hot water side. The Viessmann 222-F has a 25 gallon tank inside. While it is floor standing and larger than a wall hung Viessmann, it allows for a smaller footprint of the piping for the system.

2010 NYC Fuel Gas Code Presentation

Below is a link to the 2010 NYC Fuel Gas Code Presentation.

http://www.highefficiencyheatingnyc.com/2013/07/2010-nyc-fuel-gas-code-presentation.html

The completion of Avenue C - Viessmann Vitodens 200W

This was a very difficult project for us due to the installation of a new gas service from the street. These projects require a lot of back and forth between the utility company, the building department, and the contractor. Many requirements must be met before the gas line is provided which means much of the project is done in stages. Our video system was put in place in the middle of this project which took the better part of a year to complete.

Video 1 from March 31st shows the old boiler being removed. Each section was vacuumed and cleaned before it was taken apart to ensure that the dirt did not go all over the boiler room. All the equipment was covered in plastic to protect it.

Each video is 30 -80 seconds long showing the day's work. Watch a heating system installation in only a few minutes!